Measurement systems and data acquisition at “MS Annika Braren” successfully installed and running

To study the efficiency of the Flettner Rotor within the FlettnerFLEET project, it is essential to know the incoming and representative wind conditions of the ship as well as the vibrations and deflections of the rotor itself. Thus, the scientists set up a comprehensive measurement system, consisting of a rotor and a wind measurement system, to understand, evaluate, and consequently improve the rotor performance. After intensive planning, the IWES-team used the time during the cargo discharge in the port of Brake and the travel time to and from Brunsbüttel for the installation on April 29th, 2024.

The rotor measurement system

The mechanical measuring system at the rotor acquires strain sensors to determine the bending moments and laser distance sensors to investigate the deformation of the rotor. Acceleration sensors were also installed to acquire the information of the vibration of the rotor during different operational states. Humidity and temperature are recorded to observe the ambient atmospheric conditions. The measurements are continuously monitored remotely to achieve a high-quality data set.

Bonding and soldering the strain sensors in the stator © Fraunhofer IWES / Thole Horstmann

Entering the Brunsbüttel lock © Fraunhofer IWES / Thole Horstmann

The wind measurement system

Measurements of the wind inflow will be performed using two Lidar (light detection and ranging) systems. Since the structure of the ship disrupts the wind flow, the undisturbed wind must be measured at a sufficient distance from the ship. Lidar devices measure the wind remotely at multiple distances from their position and are therefore best suited for this mission.

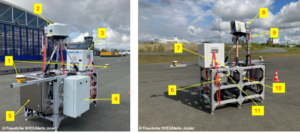

The wind measurement system shown in Figure 1 was specifically designed and assembled for this task. It contains two Lidar devices:

- The nacelle Lidar (no. 2 in Figure 1) is pointed forward to the ship movement direction and measures the wind flow at various distances in front of the ship.

- The profiling Lidar (no. 3 in Figure 1) is pointed upward and measures the wind flow at various heights above the ship.

Apart from the Lidars, the wind measurement system contains secondary sensors recording data such as position, movement, and atmospheric conditions. Furthermore, the Lidar system is equipped with communication devices that allow remote data transfer and system control.

Figure 1: Lidar wind measurement system. Components: 1) GPS antennas, 2) Nacelle Lidar optical head, 3) Profiling Lidar, 4) Nacelle Lidar processing unit, 5) Communication and control unit, 6) Water tank, 7) Satellite antenna, 8) Weather station, 9) GSM antenna, 10) Power supply unit, 11) Motion sensor

Since the installation, data is sent daily to the Fraunhofer IWES servers via mobile data. The data is continuously monitored to ensure that the wind measurement system is working as expected, which can be confirmed as a high correlation between both Lidar measurements and plausible secondary sensor data can be seen (e.g. no motion when the ship is at a harbor).

Figure 2: Location of the Lidar wind measurement system on the “MS Annika Braren”. View from the compass deck (left) and view from the side of the ship (right).

What’s next?

Currently, the team at Fraunhofer IWES is working on cleaning and correcting the wind data using the motion data recorded by the secondary sensors. Furthermore, the plausibility of the processed wind data will be confirmed by comparing it to fifth generation reanalysis dataset ERA5. Finally, the processes will be automated, and the data will be provided to the project partners for further analysis.